About Us

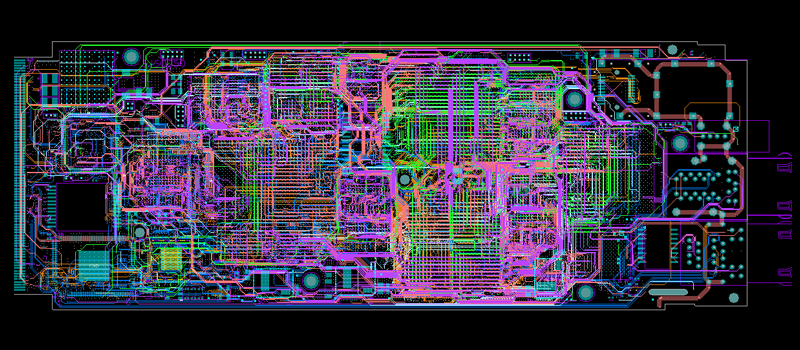

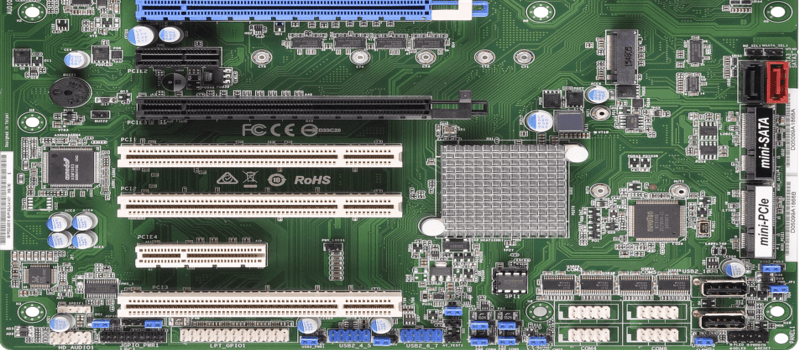

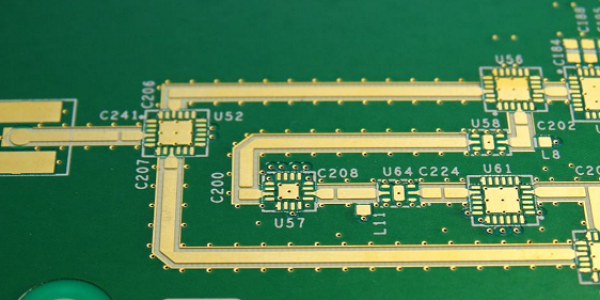

Founded in 2017, LiTE Design has established itself as a leading innovator in the fields of PCB design, software design, and development, along with a variety of allied services. We specialize in providing complete, customized electronic design solutions, tailored to meet the unique needs of our clients.

At LiTE Design, our team is composed of highly skilled and motivated professionals with deep industrial experience across diverse engineering domains. Our expertise spans FPGA, ARM, MIPS, Blackfin processors, and signal integrity (SI) analysis, enabling us to handle complex and varied design challenges.

Services

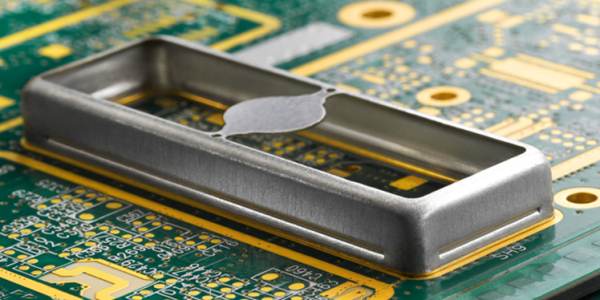

EMI/RFI Shielding

EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding are crucial for protecting sensitive electronics from external interference that can degrade performance or cause malfunctions. We provide comprehensive EMI/RFI shielding solutions designed to block unwanted signals, ensuring stable and reliable device operation. Our shielding techniques are tailored to meet industry standards, optimizing both device efficiency and compliance with regulatory requirements.

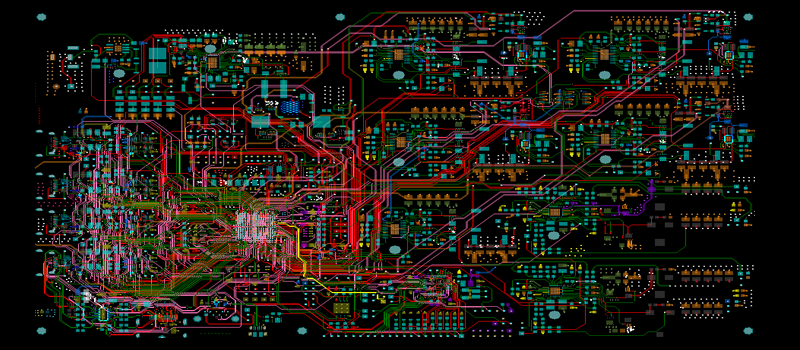

High-Speed Signal Design at Rate of 10GBPS

Our high-speed signal design services focus on ensuring optimal signal integrity for systems operating at rates up to 5GBPS. These designs are critical for high-performance computing, telecommunications, and data transmission applications. We meticulously plan signal routing, minimize losses, and mitigate noise issues to achieve robust, high-speed data transfer, maintaining the performance and reliability required by modern electronic systems.

Differential Impedance Control

Differential impedance control is essential for maintaining signal integrity in high-speed designs, particularly in differential signaling environments. We specialize in fine-tuning the impedance of differential pairs to ensure minimal signal reflection and crosstalk. Our expertise helps optimize the performance of circuits that require precise impedance matching, ensuring that they function seamlessly even under challenging conditions.

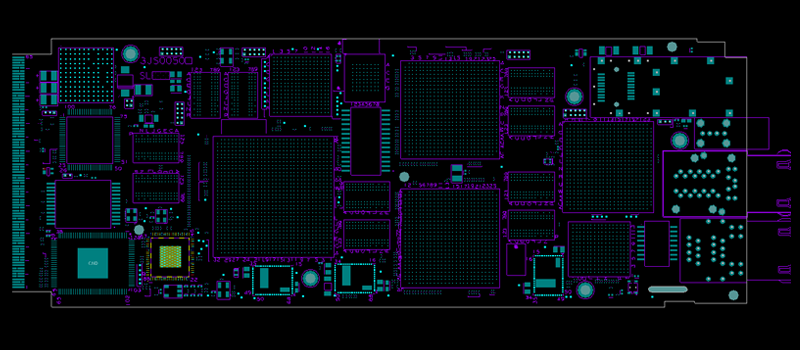

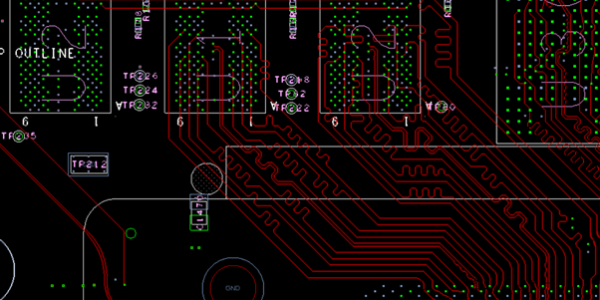

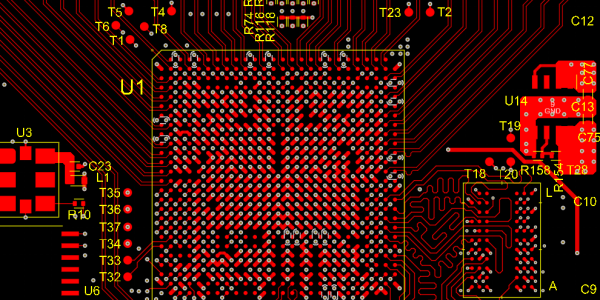

EMC/EMI Fine Pitch BGA Layout

We provide specialized services for designing fine pitch Ball Grid Array (BGA) layouts with an emphasis on electromagnetic compatibility (EMC) and EMI management. This ensures that densely packed components on printed circuit boards (PCBs) maintain proper performance without signal interference. Our design process integrates precise routing techniques that mitigate potential EMI, providing optimal PCB functionality even with compact and intricate layouts.

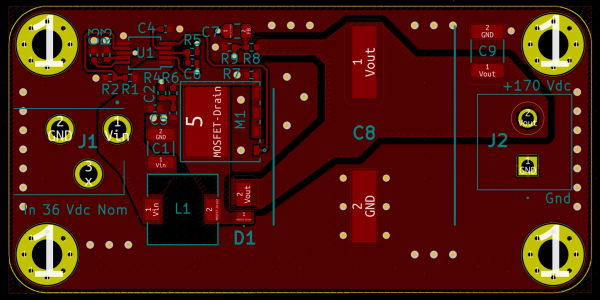

High Power Voltage Designs

High-power voltage design requires careful consideration of thermal management, power distribution, and component selection to prevent power losses and ensure system efficiency. We offer tailored solutions for designing circuits that can handle significant power loads while maintaining stability and performance. Our expertise in power electronics enables us to deliver robust designs for applications such as power converters, industrial equipment, and more.

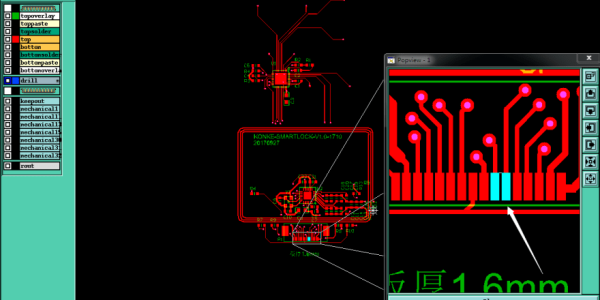

Design for Manufacturability (DFM)

Our Design for Manufacturability (DFM) services focus on optimizing designs to ensure efficient and cost-effective production. By considering manufacturing constraints early in the design process, we help reduce errors, improve yields, and streamline assembly processes. Our DFM approach ensures that your product can be manufactured reliably at scale while minimizing production risks and costs.

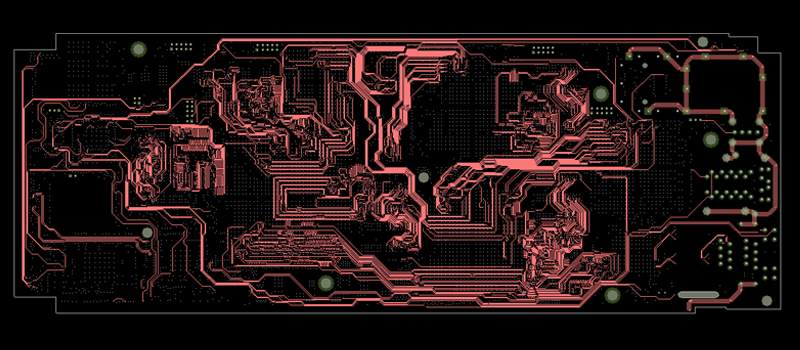

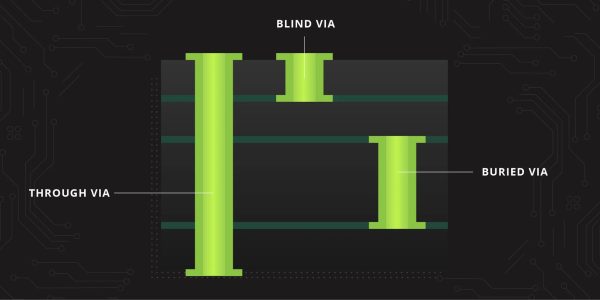

Blind, Buried & Micro Via Design

Our team is experienced in the design of complex PCB technologies like blind, buried, and micro vias, which are used to create multilayer connections without consuming surface space. These advanced via techniques allow for more compact, high-density PCBs, essential for modern electronics such as smartphones, IoT devices, and advanced computing systems. We ensure proper via placement and structure to enhance signal integrity and reliability.

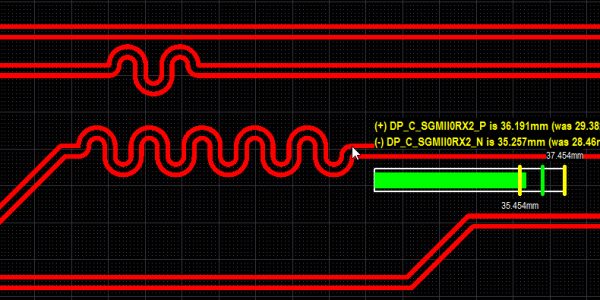

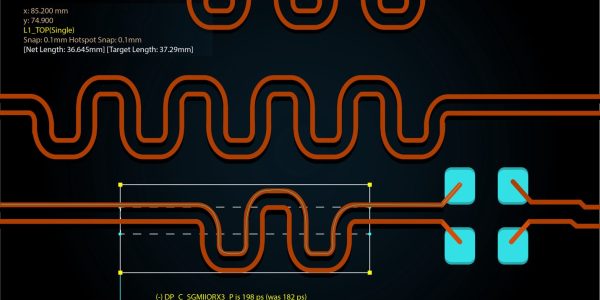

Matched Length Traces with Pin Delay

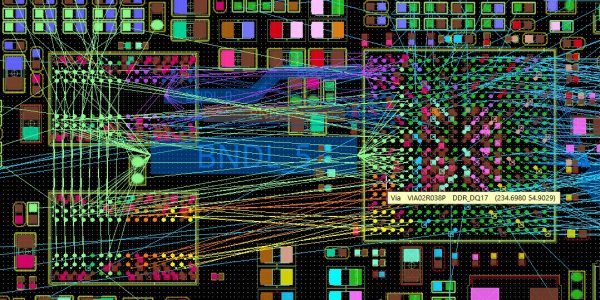

We offer matched-length trace design services that synchronize signal travel times across PCB traces, essential for high-speed digital circuits. By carefully routing traces to ensure that signals arrive at their destination simultaneously, we reduce timing mismatches and ensure proper data transmission. Pin delay compensation further fine-tunes timing, ensuring reliable performance in applications like DDR memory and high-speed interfaces.

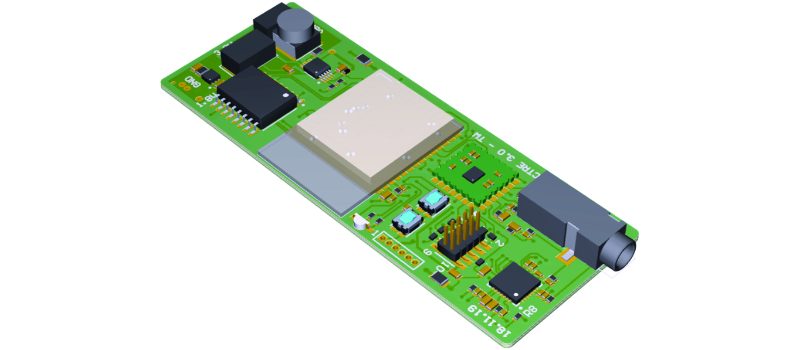

Antenna PCB Design

Components should be placed as close together as possible to minimize trace lengths. RF components, such as amplifiers and filters, should be oriented to maintain a direct signal path. Microstrip and Strip line: These are common transmission line structures used in RF PCB design. Microstrip involves a trace on a substrate above a ground plane, while strip line is sandwiched between two ground planes.

DDR5 with Balanced T Routing or Fly-By Topology

We provide expertise in DDR5 memory layout, using advanced techniques like balanced T routing or fly-by topology to ensure optimal signal timing and integrity. These approaches help in synchronizing memory signals across multiple devices, reducing noise and crosstalk, and improving data transfer speeds. Our designs ensure that your memory architecture performs efficiently, even in demanding, high-bandwidth applications.